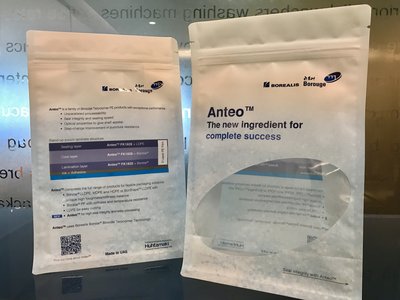

SINGAPORE, NEW DEHLI and BANGKOK, Nov. 16, 2017 /PRNewswire/ -- Borouge, leading provider of value-creating plastics solutions, recently launched Anteo™, a new family of linear low density polyethylene (LLDPE) packaging grades for the packaging market.

The global launch of Anteo in October 2017, held jointly with Borealis, was hosted in three different geographic locations -- in Austria, Abu Dhabi and Shanghai. Borouge is now excited to introduce Anteo to our customers and value-chain partners in Southeast Asia through a series of roadshows in cities including Jakarta, New Delhi, Bangkok, Kuala Lumpur and Ho Chi Minh City.

A complete flexible packaging solution

Boasting a unique combination of end-use properties for high-performance film applications, Anteo completes the solution offer for high performance, multilayer flexible packaging applications using Borealis Borstar® Bimodal Terpolymer (BBT) technology.

The result: unique polyethylene resins with superior processability. This property is augmented by other high performance-related attributes like flexibility, stiffness, toughness, purity, outstanding sealability, and appealing optics.

Anteo: the new ingredient for complete success in flexible packaging

As the key ingredient for higher performance and more sustainable multilayer applications, Anteo opens up a range of exciting application opportunities, thanks to its unique combination of superior end-use properties. Having been tested and confirmed by over 100 Borealis and Borouge customers around the globe, the proven benefits of Anteo span the entire value chain:

- Unparalleled processability: easy processability at lower extruder pressure (over 15% less than conventional metallocene LLDPE sealants), with the derived benefit of lower energy consumption.

- Seal integrity and sealing speed: high speeds can be achieved when used as sealing material in laminated/non-laminated film, resulting in lower energy consumption and less material waste.

- A step change improvement in puncture resistance: an important contribution to reducing spoilage and/or potential damage to pack contents.

- Pleasing optics for enhanced shelf appeal.

Uniquely made in the UAE

Borouge currently produces the Anteo grades at the Ruwais plant in the United Arab Emirates (UAE). The reliable supply of Anteo to customers around the world is assured thanks to Borouge's production, material handling, and global supply chain capabilities.

The first grades in the growing Anteo product family, Anteo™ FK1820 and Anteo™ FK1828, are now commercially available in Europe, the Middle East, Russia, Africa and Asia

"Borouge is always looking to develop new solutions that create value in the packaging industry. Anteo's processability and sealing performance clearly deliver superior efficiency, reliability, and quality in both film conversion and in the packaging of consumer and industrial goods," says Michael Pell, Senior Vice President, Marketing. "As a business enabler to our partners, we are excited to bring the Anteo advantage to Southeast Asia, and to continue to be a catalyst for innovation in the packaging industry."

About Borouge

Borouge is a leading petrochemical company that provides innovative, value creating plastics solutions. A joint venture between the Abu Dhabi National Oil Company (ADNOC), one of the world's major oil and gas companies, and Austria based Borealis, a leading provider of chemical and innovative plastics solutions; Borouge is a groundbreaking international partnership at the forefront of the next generation of plastics innovation.

With its base in the United Arab Emirates and Marketing & Sales head office in Singapore, Borouge employs more than 3,000 people representing over 40 nationalities and serves customers in 50 countries across the Middle East, Asia and Africa.

Building on the unique Borstar® and Borlink™ technologies and over 50 years of experience in polyolefins, Borouge provides innovative, sustainable and value creating plastics solutions for packaging, infrastructure, energy, mobility, agriculture and healthcare applications that address global challenges such as climate change, food protection, access to fresh water, energy conservation, healthcare and waste management.

In 2010 Borouge tripled the annual production capacity of its plant in Abu Dhabi to 2 million tonnes, and in 2014 Borouge successfully commissioned its Borouge 3 expansion plant, increasing the Company's annual capacity to 4.5 million tonnes of polyethylene and polypropylene and making Borouge's site in Ruwais, UAE, the world's largest integrated polyolefins complex.

Borouge has expanded its commercial and logistics network in the Middle East and Asia, established a world-class Innovation Centre in Abu Dhabi and expanded its Application Centre in Shanghai. Focused on its mission, 'value creation through people and innovation', Borouge ensures that its customers are provided with differentiated products with improved reliability of supply throughout the value chain.

Borouge is committed to the principles of sustainability and is a signatory of the chemical industry's Responsible Care® Global Charter. Together with Borealis, Borouge is proactively addressing the world's water and sanitation challenges through the Water for the World™ and Waste Free Environment initiatives.

Visit www.borouge.com

Learn more about

Borouge at www.borouge.com

Borealis at www.borealisgroup.com

Water for the World at www.waterfortheworld.net