PUBLISHED ONOctober 29, 2018 1:56 AM

|

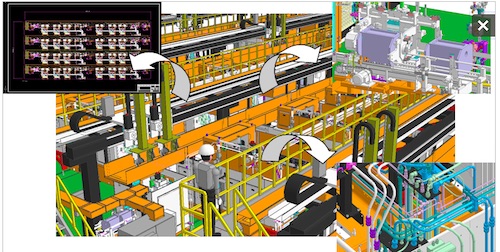

Example of design and use of large-scale data with iCAD SX V7L7 |

|

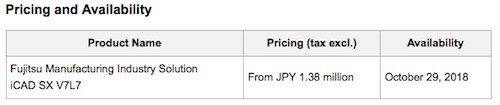

Pricing and Availability |

TOKYO, Oct 29, 2018 - (JCN Newswire) - Fujitsu today announced the Japan launch of iCAD SX V7L7, the latest version of the Fujitsu Manufacturing Industry Solution iCAD SX, its 3D CAD software for industrial machinery design, incorporating a proprietary 3D CAD engine, the world's fastest. iCAD SX V7L7 delivers a huge boost in the processing performance of 3D data, making it ideal for systems such as large-scale distribution systems, including materials handling(1), that use a large number of parts. The new product triples the number of parts that can be handled and cuts the time required to refresh cross-section diagrams in half. As a result, it becomes possible to conduct assessments in iCAD based on 3D data of the layout of an entire factory, workers paths of movement for "takt times," a term that refers to the average time between the start of production of one unit and the start of production of the next unit, and installation processes which had previously been difficult in CAD. The new software version vastly decreases customers' design work and supports a quick start to production.

Background

In order to increase their competitiveness, businesses in industries that use large-scale equipment need to improve their ability to develop increasingly complex products and shorten their time to market. In design offices, there is demand for using 3D data in the design and assessment of worker movement paths and the layout of mechanical equipment, to raise manufacturing productivity. The large volumes of 3D data generated for large-scale factories or mechanical equipment, however, makes it difficult to support the design of an entire factory's layout. Consequently, addressing how to process large-scale projects, such as with performance improvements, has been an issue.

https://www.acnnewswire.com/topimg/Low_iCADSXV7L7.jpg

Example of design and use of large-scale data with iCAD SX V7L7

Product Features

1. Support for large data volumes (tripling the number of parts that can be processed)

Memory consumption has been greatly reduced by optimizing the massive amounts of externally referenced parts information and parts structures. The improvement results in a three-fold increase in the number of parts that can be handled in iCAD, which makes it possible to design 3D data for an entire factory, including the mechanical equipment. iCAD will not only prove useful for assessments of factory layout and takt time, but will now also allow any department to make use of 3D data. For instance, the new solution will enable sales departments to use the data in proposals to customers, or could support manufacturing units doing construction or installations. By reducing post-design reworking and streamlining installation processes, the product additionally supports early production starts.

2. Accelerated creation of 2D cross-section diagrams (cutting work in half)

The processing performance for the display of minor elements and hidden elements during the creation of 2D cross sections has been increased, slashing diagram refresh times by half. To address the creation of partial cross sections, which was previously time consuming, a design support function comes as standard, further reducing the time needed to make cross-section diagrams.

3. Streamlined wiring assessments using 3D data (shrinking assessment times by 30%)

A new feature has been added so that the user can search for wiring connections in parts data from large volumes of complex 3D data, display the shortest wiring route in an easy-to-view manner. This feature decreases the time needed to conduct assessments of wiring by 30%.

Pricing and Availability

https://www.acnnewswire.com/topimg/Low_ProductAvailabilityiCADSXV7L7.jpg

Sales Target

17,000 licenses in fiscal 2018 (Fujitsu's fiscal year ends March 31).

(1) Materials handling Dealing with objects, such as raw materials, works-in-progress, and finished products that move in a manufacturing or distribution site, including on conveyors or in automated warehouses.

About Fujitsu Ltd

Fujitsu is the leading Japanese information and communication technology (ICT) company, offering a full range of technology products, solutions, and services. Approximately 140,000 Fujitsu people support customers in more than 100 countries. We use our experience and the power of ICT to shape the future of society with our customers. Fujitsu Limited (TSE: 6702) reported consolidated revenues of 4.1 trillion yen (US $39 billion) for the fiscal year ended March 31, 2018.

For more information, please see www.fujitsu.com.

This release at www.fujitsu.com/global/about/resources/news/press-releases/.

Contact:

Fujitsu Limited Public and Investor Relations Tel: +81-3-3215-5259 URL: www.fujitsu.com/global/news/contacts/

Copyright 2018 JCN Newswire. All rights reserved. www.jcnnewswire.com