Old dog, new tricks: SMRT upgrades 8-year-old C151B train to pilot predictive maintenance tech

PUBLISHED ONDecember 18, 2025 12:53 PMBYSean Ler

PUBLISHED ONDecember 18, 2025 12:53 PMBYSean LerThere's a saying that you can't teach an old dog new tricks, but rail operator SMRT may just have shown train commuters otherwise with their first upgraded fifth-generation C151B train.

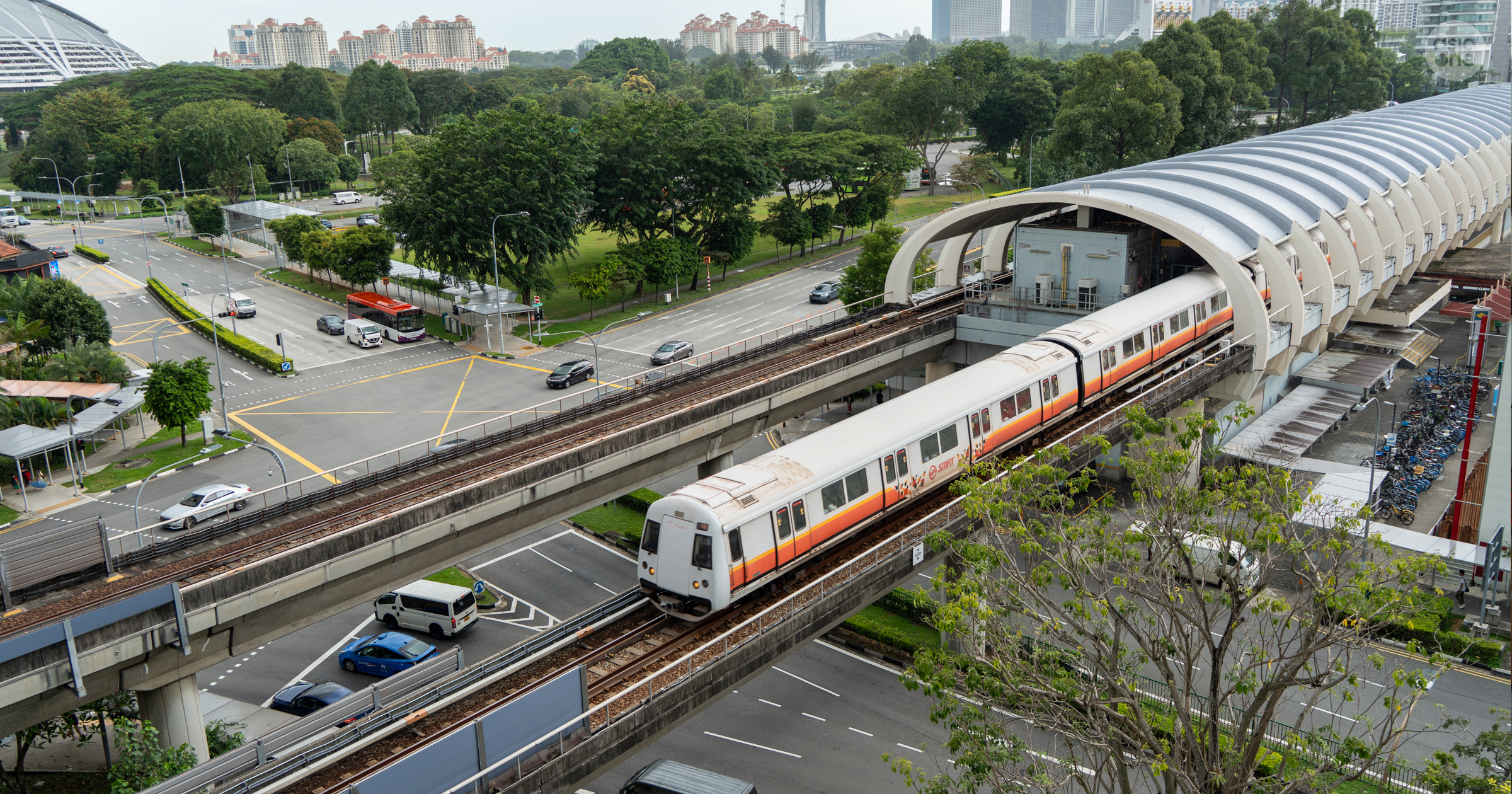

For those who commute frequently on the MRT's North-South and East-West lines (NSEWL), the C151B is a familiar sight. Forty five of these fifth-generations trains have been in service since 2017.

Along with 35 fourth-generation C151A and 12 sixth-generation C151C trains, all 92 trains will need to receive upgrades, typically carried out when trains reach around 15 years old.

Specifically for the C151Bs, they are expected to be upgraded by mid-2030s.

In 2024, SMRT partnered with Chinese train manufacturer CRRC Sifang, supported by the Land Transport Authority (LTA), to develop a proof-of-concept (POC) train.

The intent is to improve rail reliability and commuter comfort.

The C151B was selected for the POC as it operates on the NSEWL — Singapore's oldest and busiest rail corridors — with trains operating under heavy loads daily.

As part of the upgrade, about 180 new sensors were added to the train, on top of the 300 existing sensors.

SMRT said the new sensors are installed in hard-to-access areas such as the train's undercarriage.

There are also monitoring systems which assesses the health and condition of critical train components and systems, structure as well as the undercarriage of the train.

AsiaOne was among the media to preview the first POC train at Bishan Depot on Dec 18.

The first thing that stood out was the optimised temperature onboard the POC train. This, according to SMRT, is due to the upgraded energy-efficient air-conditioning and ventilation system.

Apart from utilising eco-friendly refrigerant, the new system also has embedded sensors that help to detect filter blockages and leaks so that proactive maintenance can be carried out.

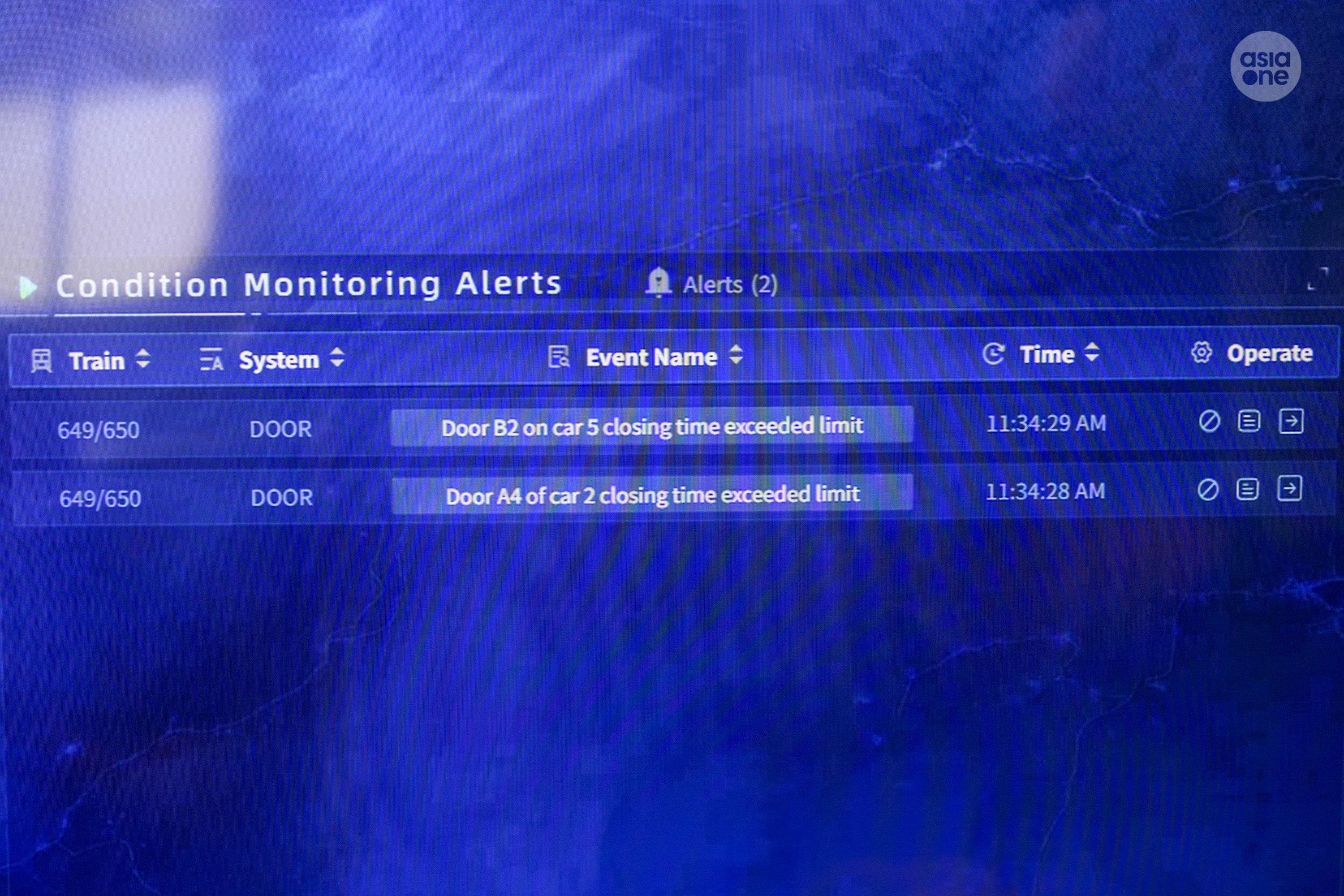

Another highlight is the new condition monitoring system (CdM). It is used to continuously monitor the health and performance of critical train components and systems.

As compared to the existing train information and management system (TIMS) — which alerts the maintenance team of component failures — the new CdM identifies potential issues before they trigger TIMS.

The CdM performs diagnostics automatically on components such as the power systems, air-conditioning systems, door control systems and brake systems.

During the preview, the media was shown how the system could detect potential faults — even if it occurred in milliseconds.

SMRT engineers simulated a train door fault which was not apparent to members of the media. However, the system detected that the door had closed milliseconds slower than it should.

The exact doors were also pinpointed, negating the need for the maintenance crew to test every train door in the identified train car, saving manpower and time.

Other upgrades include the structural health monitoring system and the bogie monitoring system.

The former tracks and trends micro-changes in the stresses and strains of the main structural components like car bodies and bogies.

The bogie refers to the undercarriage of a train, which houses the suspension systems, axles, gearboxes and wheels.

It enables the maintenance crew to detect early signs of degradation, thereby enabling timely intervention to minimise unexpected downtime — such as the East-West Line disruption in September last year.

On Sept 25, 2024, the axle box of a faulty first-generation KHI train — which had been in service for more than 35 years — fell, damaging trackside equipment and a 2.55km stretch of track between Dover Station and the Ulu Pandan Depot.

This caused a six-day train service disruption between Boon Lay Station and Queenstown Station, affecting approximately three million passenger journeys.

SMRT said that validating technologies to be rolled out during the subsequent upgrades will allow them to take a "proactive approach" to improving rail reliability through a better understanding of the latest technologies, testing alternative solutions and enhancing commuter comfort.

"The intent is to identify faults before they happen. This is essential for futureproofing as well as meeting growing commuter demands as the rail network expands," an SMRT spokesperson said.

Once validated, SMRT will work with LTA to implement these solutions into the 91 other trains as part of their mid-life upgrades.

[[nid:725287]]